Home »

Our Products » Ventilation & Exhaust Units

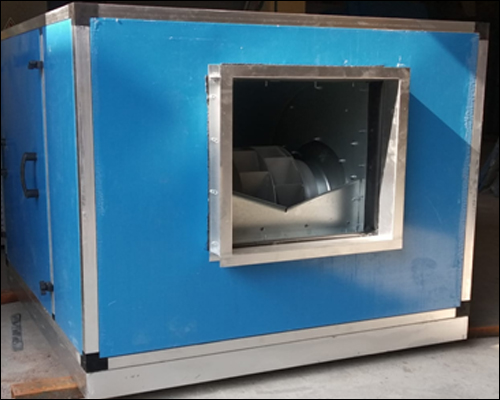

Fan Section Manufacturers

We are one of the best quality Fan Section Manufacturers, Ventilation & Exhaust units Manufacturers.

AMCS Cooling Systems has emerged as a leading provider of innovative ventilation and exhaust solutions, revolutionizing the way we manage indoor air quality and comfort. With a commitment to excellence and a focus on customer satisfaction Ventilation & Exhaust units Manufacturers, AMCS have range of products designed to meet the diverse needs of residential, commercial, and industrial environments. AMCS understands that every space has unique requirements. Their team of experts works closely with clients to assess their specific needs and recommend the most suitable ventilation and exhaust systems. Whether it's a small office or a large manufacturing facility, AMCS has the expertise to deliver customized solutions.

Ventilation & Exhaust units Manufacturers

AMCS is dedicated to promoting sustainability. Their products are designed to optimize energy consumption, reducing operational costs and minimizing environmental impact. By incorporating advanced technologies and energy-efficient components, AMCS helps clients achieve their green goals. Ventilation & Exhaust units Manufacturers, AMCS is committed to providing products of the highest quality. Their manufacturing processes adhere to stringent standards, ensuring that each unit is built to last. From the materials used to the assembly techniques, AMCS prioritizes durability and reliability.

Ventilation & Exhaust units Suppliers

AMCS understands that excessive noise can be disruptive. Their ventilation and exhaust systems are engineered to minimize noise levels, creating a comfortable and productive environment. Advanced noise-reduction technologies are employed to ensure quiet operation without compromising performance. Ventilation & Exhaust units Manufacturers, AMCS specializes in developing customized ventilation and exhaust systems to meet specific requirements, such as cleanrooms, laboratories, and data centers.

RANGE:

- Floor mounted fan section are

available from 2000 CFM to 35000 CFM (Belt Driven)

- Ceiling suspended fan section are

available from 1200 CFM to 6000 CFM (Belt Driven)

CASING : (SINGLE SKIN)

- SINGLE SKIN casing in 18

/ 16 gauge pre-coated GI sheet is also available as an option.

- Access door section for easy

repair and maintenance

- Assembly is done using self

drilling and self tapping galvanized sheet metal screws.

- Floor mounted Units are skid

mounted. The base frame is rugged in construction made from galvanized

steel sheet.

- Ceiling suspended fan sections

are also available.

CASING : (DOUBLE SKIN)

- Rigid corrosion resistant

extruded aluminum section uses for more strength

- Double skin sand-witched panels

with inner skin of 24 G (0.6 mm) plain galvanized steel sheets &

outer skin of 24 G (0.6 mm) pre-coated galvanized steel sheet.

- Casing Panels are injected with

high pressure PUF insulation having density of 38±2 kg/m³.

Standard models have 25 mm thick panel.

- Access door section for easy

repair and maintenance.

- Assembly is done using self

drilling and self tapping galvanized sheet metal screws.

- Floor mounted Units are skid

mounted. The base frame is rugged in construction made from galvanized

steel sheet.

- Ceiling suspended fan section are

also available.

- Double skin casing is standard.

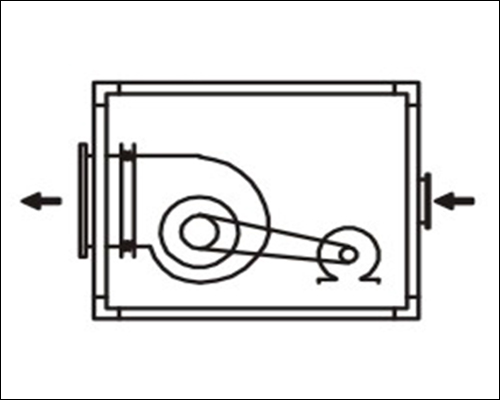

FAN & MOTOR:

- Fans are centrifugal, DIDW

forward curved. Fans are energy efficient & AMCA certified.

Horizontal fans are belt driven while ceiling suspended fan section have

both direct and belt driven models.

- Motors are TEFC, Squirrel Cage

Induction type with class 'F' insulation confirming to IS 325. Motors

are suitable for 3 phase 415±10% V, 50±5% Hz AC supply. Direct

driven motors are suitable for single phase 220 V, 50 Hz AC supply.

Energy efficient level 1 motor as per IS 12615 can be provided on

request.

- Fan & Motor are mounted on

common extruded aluminum channel base frame.

- The combined fan motor base frame

is mounted on suitable vibration isolator to minimize vibration

transmission.

- The fans are connected to the

casing through fire resistant canvass.

- Fresh air Fan Section outlet

shall have flanged connection for duct connection.

- Exhaust air Fan Section outlet

and inlet shall have flanged connection for duct connection.

- Fresh air Fan section shall be

provided with pre-filter

- Fan Section can have either of

the following air discharge orientation, Up Blast/ Top Horizontal/

Bottom Horizontal.

- Fan Section can also have

backward curved fan as an option.